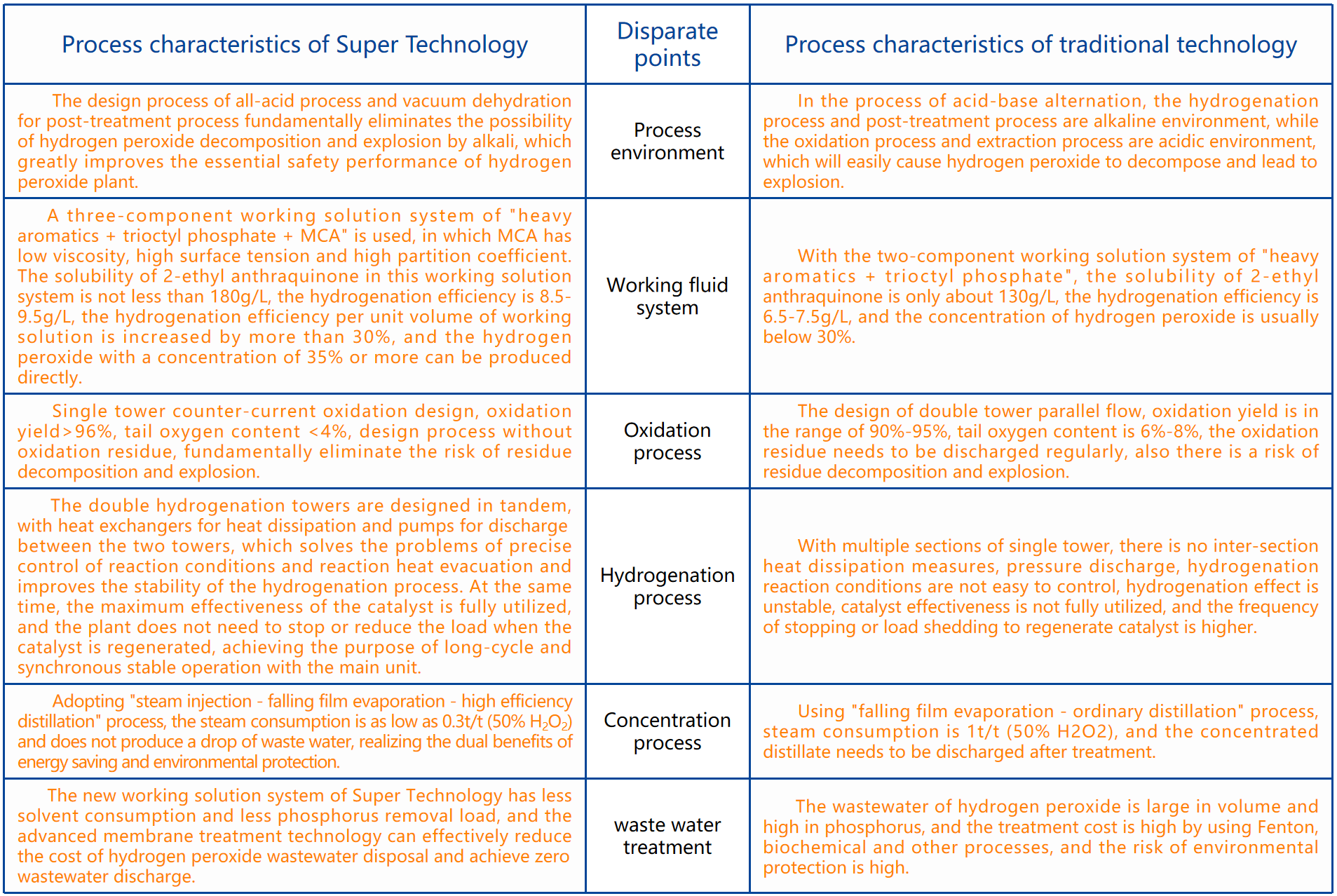

Our company Science and Technology always takes technological innovation as the foundation, relying on the innovation platforms such as the National Science and Technology Innovation Base of the Park, the National postdoctoral Research Workstation, the CNAS Certification Laboratory and the National Enterprise Technology Center, and takes the road of "introduction and digestion, joint research and development, independent development". With Dalian Institute of Chemical Physics of the Chinese Academy of Sciences, Beijing University of Chemical Technology, Wuhan University of Technology, Shanghai normal University and other universities, as well as well-known design units such as Saiding Engineering Co., Ltd., Hualu Engineering Science and Technology Co., Ltd., established a strategic partnership, set up a catalyst research and development platform in the Hubei three Gorges Laboratory, and the R & D team headed by Comrade Fu Vernon broke the foreign technical blockade. A new fixed-bed full-acid anthraquinone process for the preparation of hydrogen peroxide was independently developed and successfully applied in more than 30 projects, including the single largest fixed-bed hydrogen peroxide plant in China. Won many honors and awards, such as the national special and new "Little Giant", Hubei Enterprise Technology Center, Petrochemical Federation Science and Technology Progress Award, participated in the revision of more than 10 enterprise and group standards, and owned more than 40 patents. Continue to lead the development of hydrogen peroxide technology, and export reverse technology abroad.